Centrifugal exhaust fans are commonly used in industrial and commercial settings to ventilate and exhaust air. These fans can consume a lot of energy, which can increase operating costs. However, there are several ways to reduce the energy efficiency operation cost of centrifugal exhaust fans:

1.Choose the right size: Choosing the right size of fan for your application can significantly reduce energy costs. An oversized fan will consume more energy than necessary, while an undersized fan will not effectively ventilate the area.

2.Use Variable Frequency Drives (VFDs): VFDs can help to reduce energy costs by controlling the speed of the fan. By adjusting the fan speed to match the ventilation requirements of the space, energy can be saved.

3.Optimize fan blade angles: The angle of the fan blades can have a significant impact on the energy efficiency of the fan. Optimizing the blade angles can improve the airflow and reduce energy consumption.

4.Clean and maintain the fan regularly: A dirty fan can reduce the efficiency of the fan and increase energy consumption. Regular cleaning and maintenance of the fan can help to improve efficiency and reduce energy costs.

5.Use energy-efficient motors: The use of energy-efficient motors can significantly reduce the energy consumption of the fan. High-efficiency motors are designed to consume less energy while maintaining the same level of performance.

6.Install an automatic control system: An automatic control system can help to optimize the fan's operation and reduce energy consumption. This system can automatically adjust the fan's speed and ventilation based on the temperature and humidity levels of the space.

7.Insulate the ductwork: Insulating the ductwork can help to reduce energy loss and improve the efficiency of the fan. Proper insulation can help to maintain the desired temperature of the space, reducing the load on the fan.

In summary, reducing the energy efficiency operation cost of centrifugal exhaust fans involves choosing the right size, using VFDs, optimizing fan blade angles, cleaning and maintaining the fan, using energy-efficient motors, installing an automatic control system, and insulating the ductwork. By implementing these strategies, energy costs can be reduced while maintaining the desired ventilation and air quality in the space.

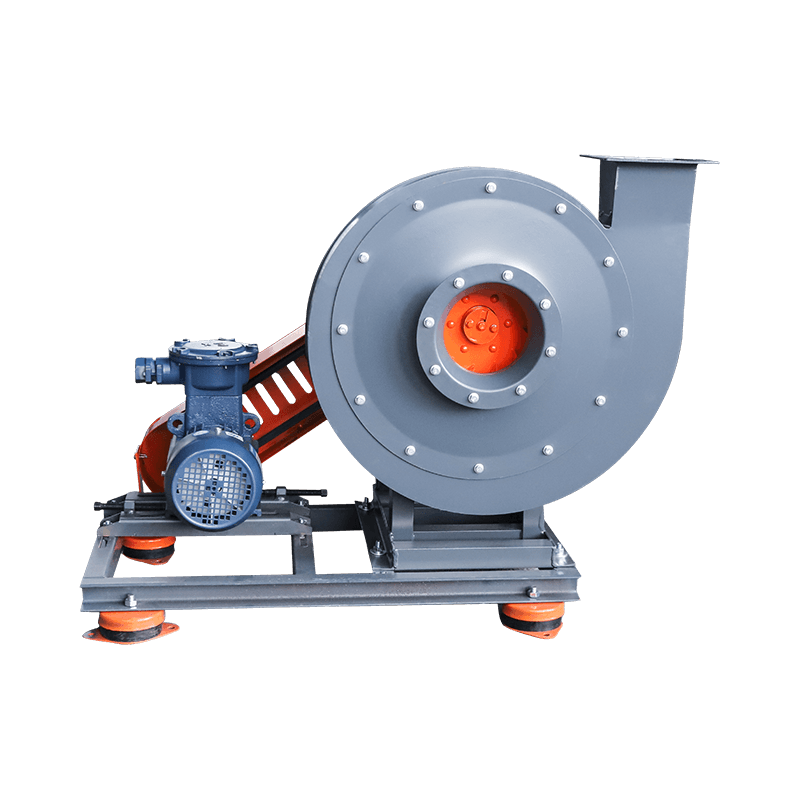

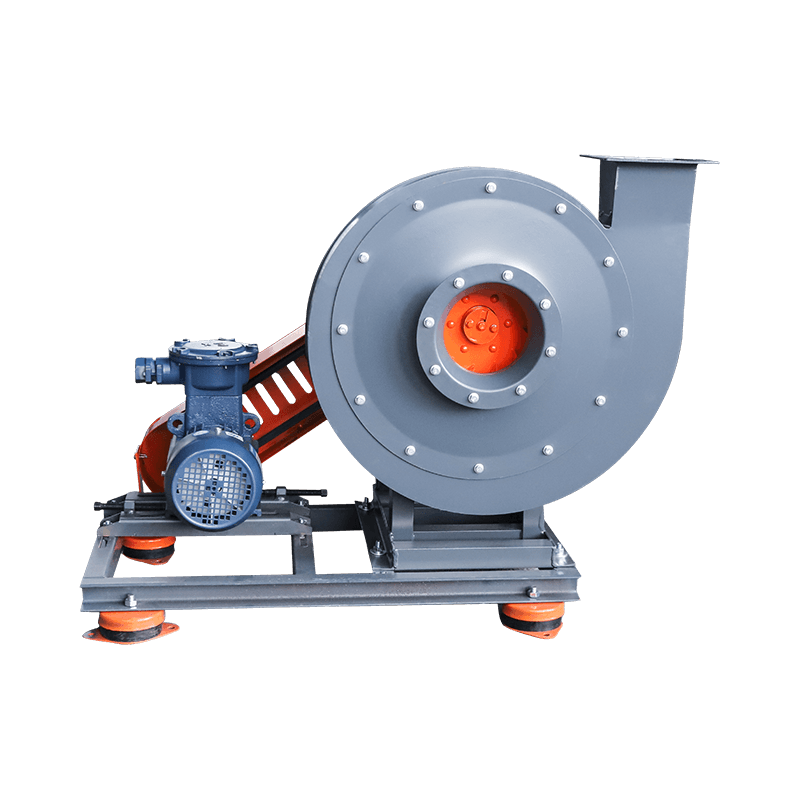

Core Performance: It Has The Characteristics Of High Efficiency, Low Noise, Flat Performance Curve And Wide Efficient Area.

Applications: Building Ventilation, Fume Removal, Dust Removal, Dust Collection, Oven And Dryer Exhaust, Combustion Air, Incinerators, Heat Recovery.

Function: The Fan Can Output Higher Gas Pressure, And Can Provide More Gas Flow At The Same Time, Low Noise.The Motor Shaft Is Elastically Connected With The Drive Shaft. It Is Not Necessary To Tighten The Belt Or Replace The Belt Frequently, And The Maintenance Workload Is Small.The Fan Is Made Of High Quality Carbon Steel, And Can Also Use Stainless Steel Or Other Metal Materials According To Customer Requirements.