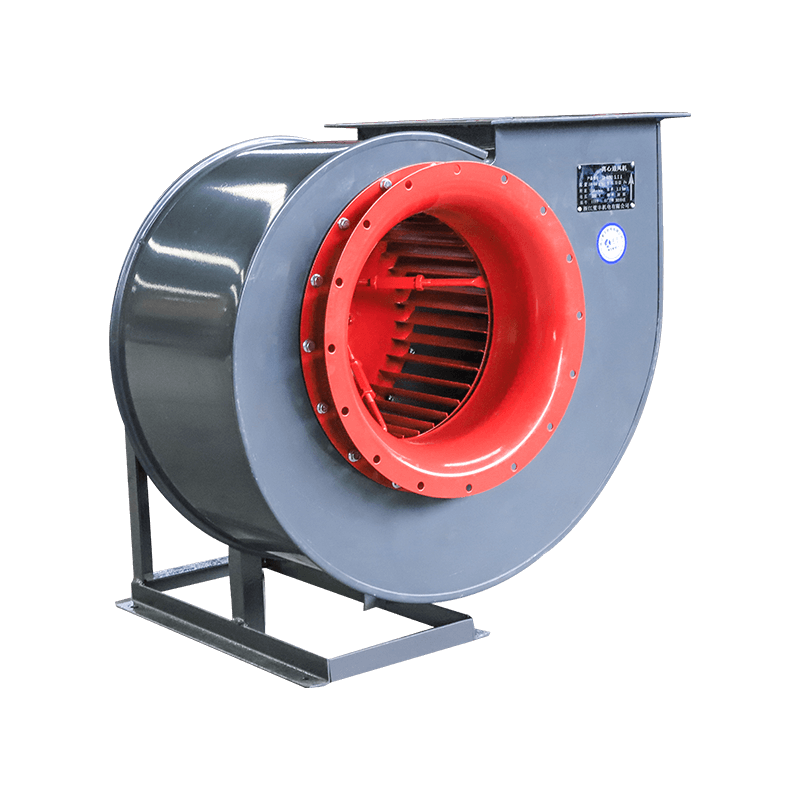

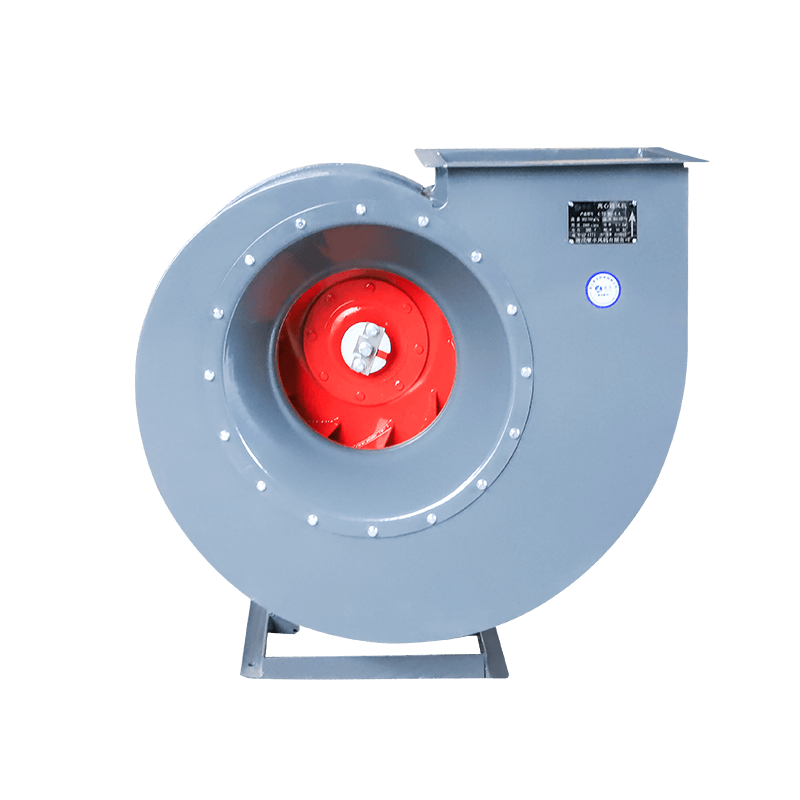

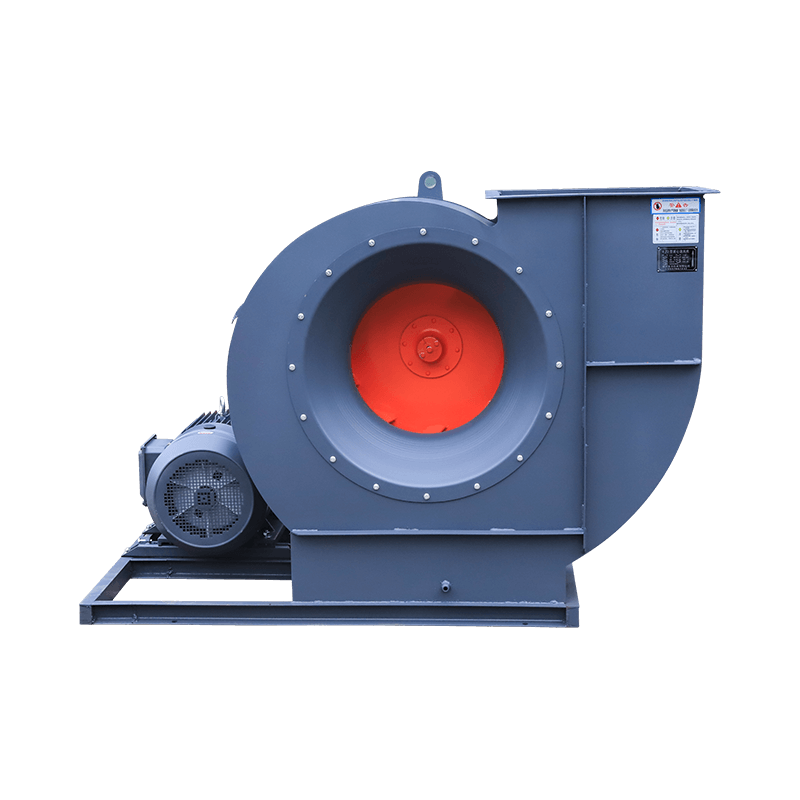

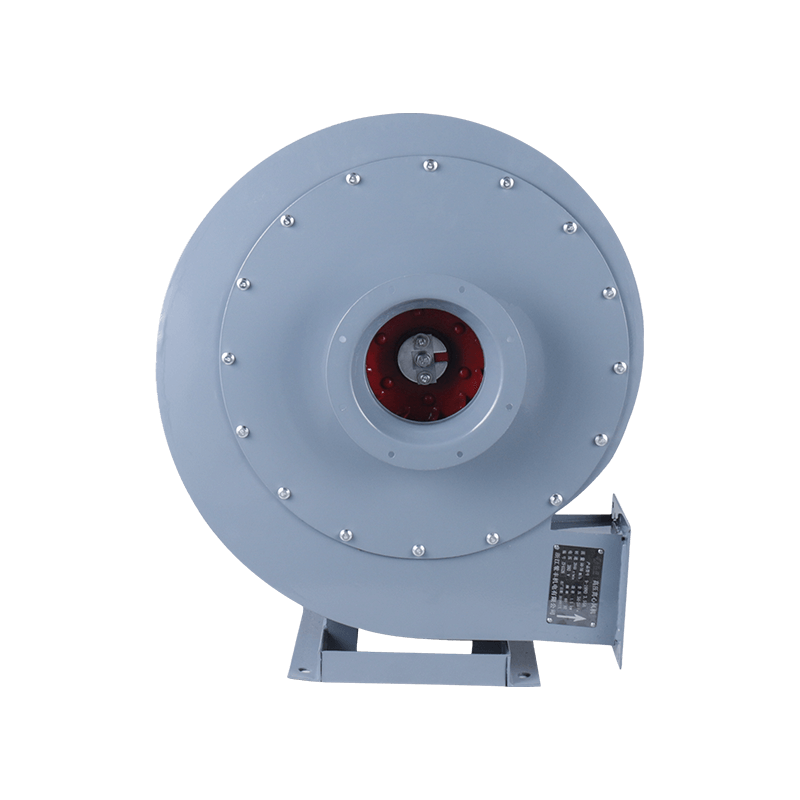

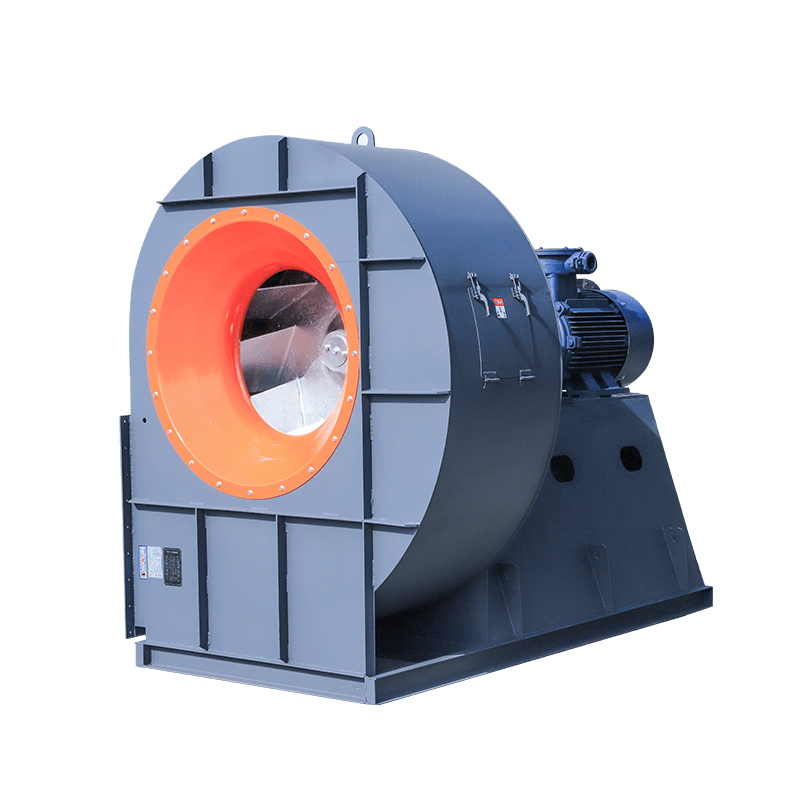

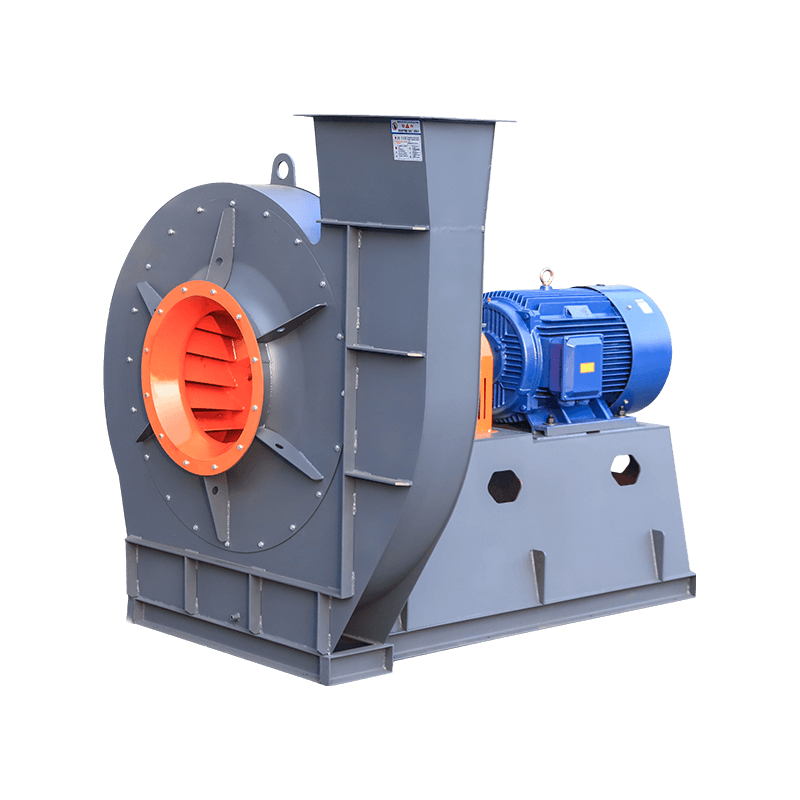

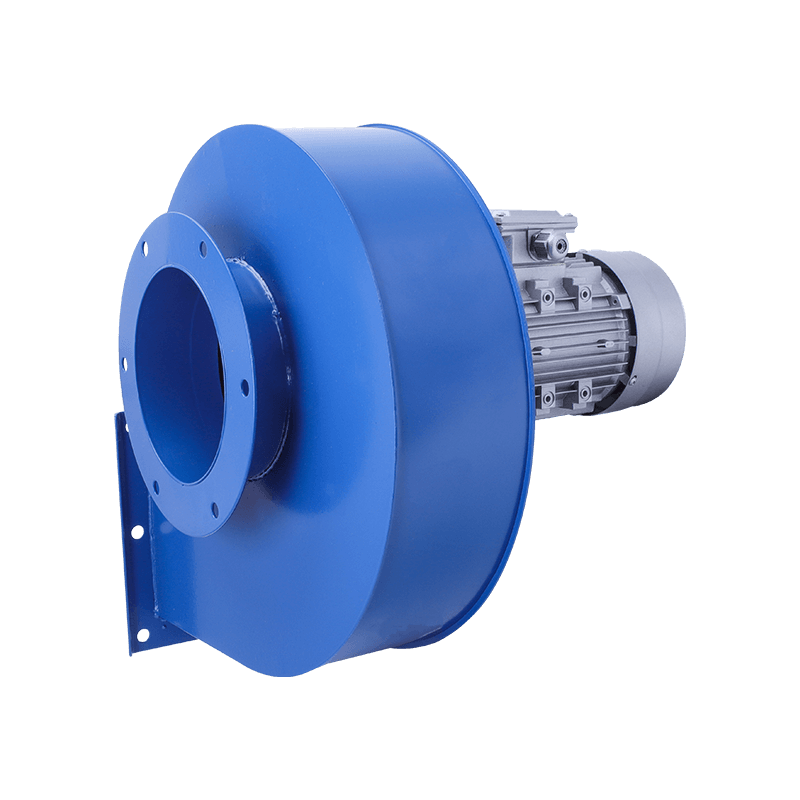

High-pressure centrifugal fans, also known as centrifugal blowers or high-pressure blowers, are mechanical devices used to move air or other gases in a direction perpendicular to the axis of rotation. These fans are designed to generate a high-pressure stream of air, making them suitable for applications where the airflow needs to be directed over a long distance or through a system with a high resistance to flow.

The high-pressure centrifugal fan works by using a rotating impeller that accelerates the air, creating a pressure differential between the inlet and outlet of the fan. The impeller blades push the air radially outward, and the resulting centrifugal force causes the air to move in a tangential direction. As the air moves through the fan housing, the volume of the air is reduced, and the pressure is increased. The air is then discharged from the outlet of the fan, typically through a duct or other conduit.High-pressure centrifugal fans are used in a variety of industrial and commercial applications, including ventilation systems, dust collection, combustion air supply, pneumatic conveying systems, and air handling units. They can handle a wide range of flow rates and pressures, making them suitable for both low-flow, high-pressure and high-flow, low-pressure applications.

Features of high-pressure centrifugal fans

The features of high-pressure centrifugal fans can vary depending on their design and application, but some common features include:

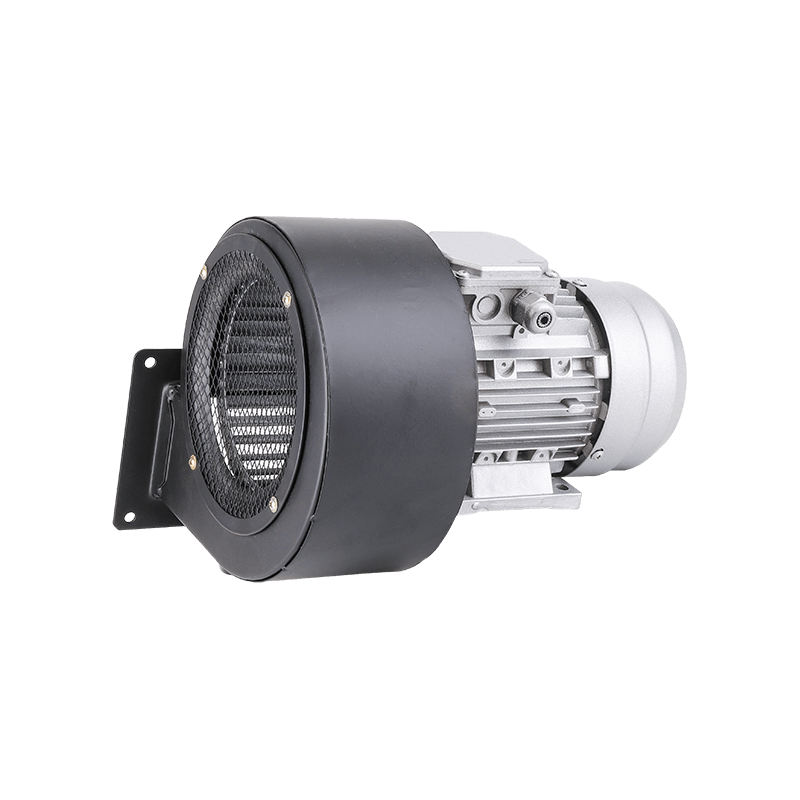

1.Impeller design: High-pressure centrifugal fans have a specially designed impeller that is capable of generating high-pressure airflows. The impeller may have backward-curved, forward-curved, or radial blades, depending on the application.

2.Housing design: The fan housing is designed to accommodate the impeller and direct the airflow. The housing may be circular, rectangular, or other shapes, and may have inlet and outlet connections for ducting.

3.Motor and drive system: The fan is driven by an electric motor, and the drive system may include a belt, coupling, or direct drive. The motor may be located inside or outside the fan housing.

4.Materials of construction: High-pressure centrifugal fans are typically constructed of heavy-duty materials such as steel, aluminum, or stainless steel, depending on the application. The impeller and housing may be coated with protective materials to increase their durability and resistance to corrosion.

5.Control systems: Some high-pressure centrifugal fans may be equipped with control systems that allow for speed control or variable airflow. This can be useful in applications where the airflow needs to be adjusted to meet changing conditions.

6.Noise reduction features: High-pressure centrifugal fans can generate a significant amount of noise, so some models may be designed with noise-reduction features such as sound-absorbing materials, acoustic enclosures, or silencers.

7.Maintenance requirements: High-pressure centrifugal fans require periodic maintenance to ensure optimal performance and reliability. Maintenance tasks may include lubrication, bearing replacement, cleaning, and inspection.