When selecting a blower fan for harsh environments, there are several factors that should be considered. These factors include:

1.Material: The material of the blower fan should be able to withstand the environmental conditions it will be exposed to. For example, a blower fan used in a corrosive environment may require a coating or a material that resists corrosion.

1.Motor protection: The motor of the blower fan should be protected from the harsh environment. This may include protection from moisture, dust, and other contaminants.

2.Temperature range: The blower fan should be able to operate within the temperature range of the environment it will be used in. If the environment is extremely hot or cold, the blower fan may require additional cooling or heating mechanisms.

3.Airflow requirements: The airflow requirements of the environment should be considered when selecting a blower fan. The blower fan should be able to provide the necessary airflow to maintain the desired temperature and air quality.

4.Pressure requirements: If the blower fan is used in an application where pressure is important, such as in a ventilation system, the pressure requirements should be considered.

5.Electrical requirements: The electrical requirements of the blower fan should be compatible with the power supply available in the environment. This includes voltage, phase, and frequency.

6.Environmental regulations: Depending on the industry and location, there may be environmental regulations that dictate the type of blower fan that can be used.

Blower Fan Manufacturers tell you that it's important to consider these regulations when selecting a blower fan for a harsh environment.

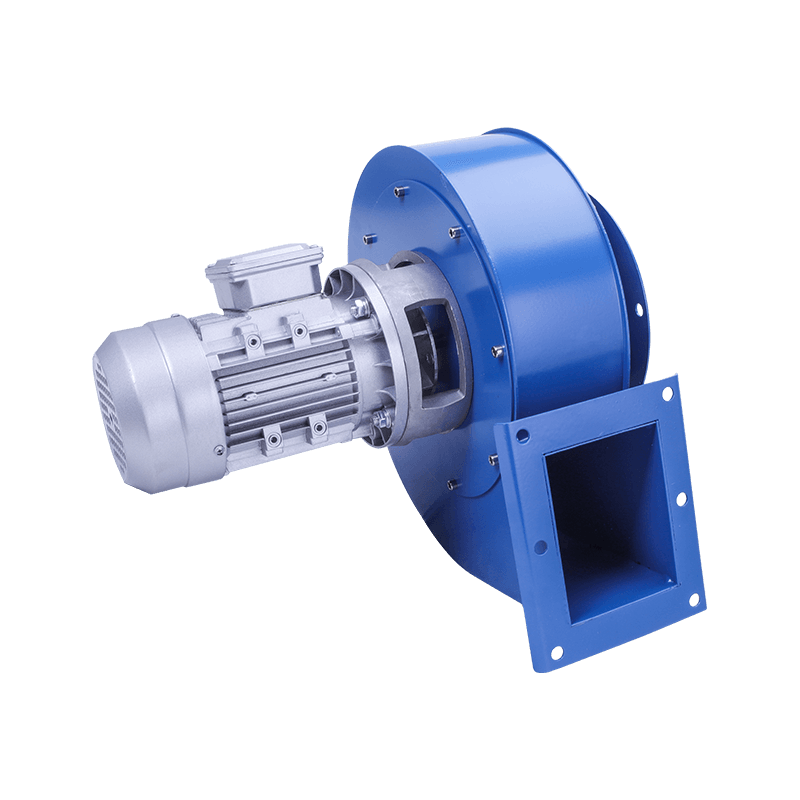

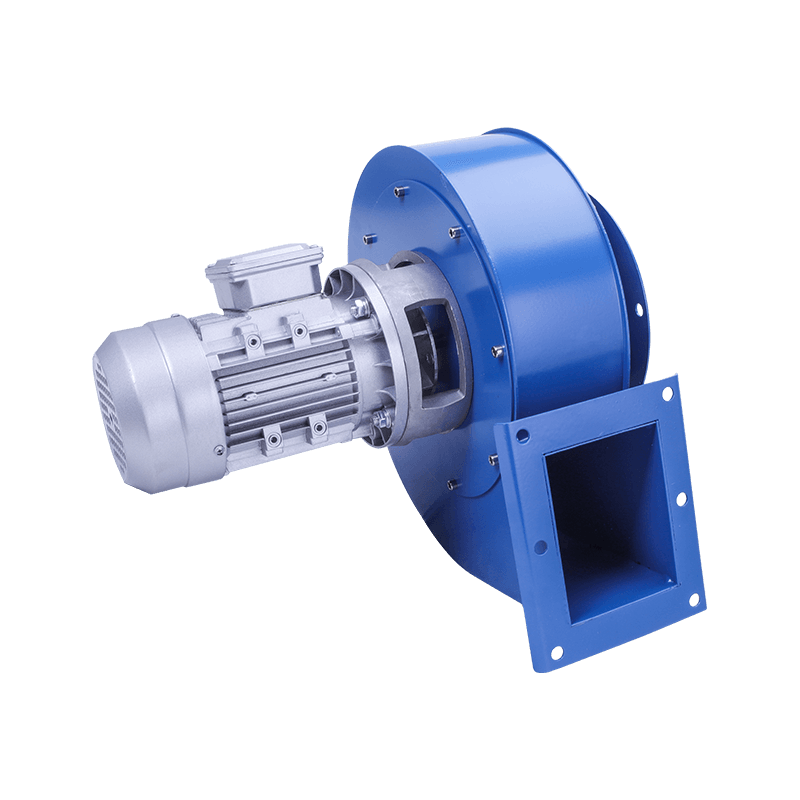

Features: High Temperature Resistance, High Efficiency, Large Air Volume, Low Vibration, Low Noise, Beautiful Shape, Centrifugal Induced Draft Fan.

Material: The Motor Is Made Of Y2 Aluminum Alloy Die-Casting Material, Which Greatly Reduces The Weight And Achieves Light Weight, Convenient Installation And Novel Shape.

Application: Heating Furnace, Hot Air Furnace, CNC Boiler, Steam Boiler, Drying, Chemical, Food, Grain Machinery And Other Related Industries